Finishing is the final but most visually and functionally defining step in any plywood project. In Indian interiors—where climate variability, aesthetic expectations, and functional wear intersect—the choice of finish isn’t just decorative, it’s architectural. The wrong finish can peel, fade, warp or crack. The right one elevates both form and durability. This guide explores the science and art behind plywood finishing in India, drawing from material science, installation methodology, and designer preferences to help you select the ideal finishing approach based on usage and environmental stressors.

Finish #1: Laminates (High-Pressure Laminates - HPL)

Laminates remain the most widely used plywood surface treatment in India for both residential and commercial spaces.

Why Use It:

-

Cost-effective and durable

-

Comes in endless colours, textures, and gloss levels

-

Scratch, moisture, and heat resistant (HPL grade)

Applications: Kitchen shutters, wardrobes, office furniture, and TV units

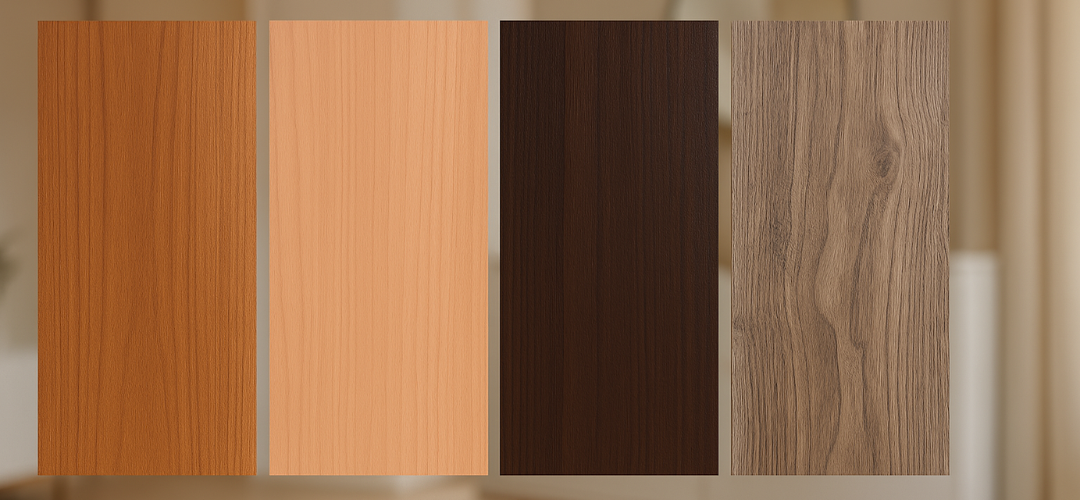

Finish #2: Natural Veneer

Veneers offer the warmth and depth of real wood while being more sustainable and easier to maintain.

Why Use It:

-

Natural grain patterns for high-end aesthetics

-

Customisable with stains or clear coats

-

Ideal for luxury interiors

Applications: Headboards, wall panelling, wardrobe shutters, dining furniture

Finish #3: PU (Polyurethane) Polish

PU is a high-performance coating known for its sleek finish and long-term protection.

Why Use It:

-

High gloss, matte, or satin variants

-

Superior resistance to stains, water, and wear

-

Provides a glass-smooth finish when done professionally

Applications: Bedroom furniture, commercial fit-outs, accent cabinets

Finish #4: Acrylic Sheets

Acrylic is a synthetic, high-gloss finish applied as a sheet or coating.

Why Use It:

-

Mirror-like shine with colour consistency

-

UV and moisture resistant

-

Suitable for contemporary and minimalist designs

Applications: Modular kitchens, vanity units, children’s furniture

Finish #5: Fabric Laminate / Leatherette

Soft-touch finishes are gaining traction in Indian high-end interiors.

Why Use It:

-

Tactile luxury

-

Noise-dampening and impact-resistant

-

Suitable for plush wardrobes and entertainment units

Applications: Walk-in closets, headboards, living room cabinetry

Best Practices for Plywood Finishing

-

Always sand and seal the base surface for adhesion

-

Match adhesive and application method to the finish type

-

Use calibrated ply for PU and veneer to prevent surface undulations

-

Edge banding is non-negotiable for long-term durability

Plyneer Finish Compatibility Assurance

Every Plyneer board is tested for compatibility across:

-

HPL lamination

-

PU polishing

-

Veneer and acrylic overlay

-

Anti-scratch and anti-bubble bonding

Pre-laminated options also available for fast-track execution.

Where to Buy Finish-Ready Plywood in India

Related Reads for Surface Design

Final Word

Finishing isn’t just the final step—it’s where function meets expression. Choosing the right finish for your plywood defines both the feel and lifespan of your space. With Plyneer’s engineered boards, you get a finish-ready foundation designed to perform as beautifully as it looks.

📞 Need help choosing the right finish? Contact Plyneer’s surface specialists today!

🚀 Explore Finish-Grade Plywood